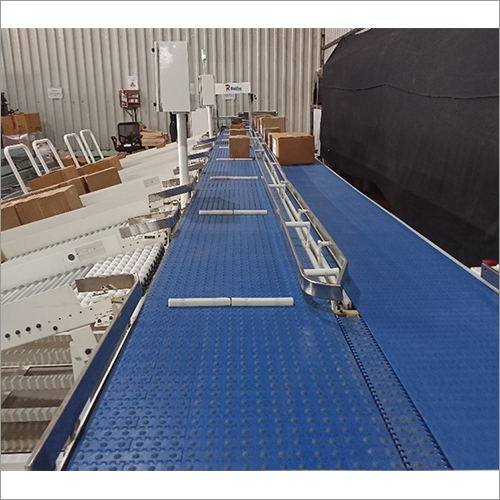

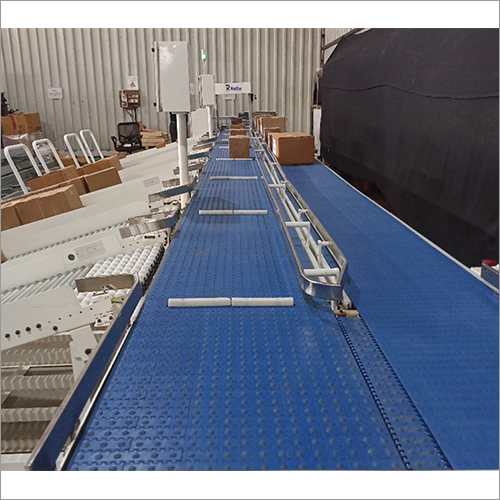

à¤à¤°à¥à¤¨à¤à¥ à¤à¤¨à¥à¤µà¥à¤¯à¤° सà¥à¤°à¥à¤à¤¿à¤à¤ सिसà¥à¤à¤®

Price 2000000-4500000 आईएनआर/ टुकड़ा

MOQ : 1 टुकड़ा

à¤à¤°à¥à¤¨à¤à¥ à¤à¤¨à¥à¤µà¥à¤¯à¤° सà¥à¤°à¥à¤à¤¿à¤à¤ सिसà¥à¤à¤® Specification

- सटीकता

- 99.8%

- हवा का दबाव

- 0.6–0.8 MPa

- वज़न

- 1200 kg

- एप्लीकेशन

- Parcel, package, and mail sorting in logistics centers

- क्षमता

- Up to 6000 parcels/hour

- उपयोग

- Industrial

- चैनल्स

- Supported up to 40 custom channels

- आयाम (एल* डब्ल्यू* एच)

- 9000 mm x 1200 mm x 1800 mm

- आउटपुट

- Automated parcel sorting to designated lanes

- एयर कंप्रेसर

- Integrated high-efficiency industrial air compressor

- पावर

- 380V/50Hz, 3-phase, 5.5 kW

- टाइप करें

- Turnkey Conveyor Sorting System

- Control System

- Advanced PLC with touchscreen HMI

- Installation

- Modular and easy to assemble on-site

- Maintenance

- Low maintenance design with easy-access panels

- Sorting Mechanism

- Automated pneumatic diverters

- Noise Level

- Less than 65 dB

- Safety Features

- Emergency stop switches and overload protection

- Conveyor Belt Material

- High-strength industrial PVC

- Sensors

- Laser scanning, barcode and QR code recognition

- Operating Temperature

- 0°C to 45°C

à¤à¤°à¥à¤¨à¤à¥ à¤à¤¨à¥à¤µà¥à¤¯à¤° सà¥à¤°à¥à¤à¤¿à¤à¤ सिसà¥à¤à¤® Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- हफ़्ता

About à¤à¤°à¥à¤¨à¤à¥ à¤à¤¨à¥à¤µà¥à¤¯à¤° सà¥à¤°à¥à¤à¤¿à¤à¤ सिसà¥à¤à¤®

We are an unparallelled exporter and manufacturer of quality approved Turnkey Conveyor Sorting System, which is available in various specifications, sizes and dimensions. The system is extensively used in various places, thus, hugely in demand and appreciated for its excellent performance. In addition to this, as per the convenience of the reputed clients, we deliver the Turnkey Conveyor Sorting System on time at reasonable price.

High-Efficiency Parcel Sorting

This system automates parcel recognition and lane assignment using laser and barcode scanning, ensuring rapid and precise sorting. The advanced PLC with a user-friendly touchscreen HMI simplifies process control for operators, while the pneumatic diverters offer smooth direction changes at high speeds for up to 6000 parcels per hour.

Robust Safety and Low Maintenance

Safety is prioritized with emergency stop switches and overload protection. The conveyor is built with accessible maintenance panels, enabling quick servicing with minimal downtime. Industrial-grade components and a low-noise profile make it ideal for intensive logistics operations.

Flexible Installation and Customization

Modular design allows for straightforward onsite assembly and supports up to 40 custom sorting channels. The integrated air compressor is engineered for efficiency, maintaining reliable pneumatic operation with minimal energy usage. The system adapts easily to facility layouts and application needs.

FAQs of Turnkey Conveyor Sorting System:

Q: How does the automated sorting process work in this conveyor system?

A: The system uses laser scanning and barcode/QR code sensors to identify parcels as they move along the conveyor. Pneumatic diverters, controlled by the advanced PLC, automatically direct items into designated lanes based on recognized codes, ensuring accurate sorting quickly and efficiently.Q: What benefits does the high-strength industrial PVC conveyor belt provide?

A: The industrial PVC belt delivers durability, reduced wear, and reliable performance, supporting sustained high-capacity operations while requiring minimal maintenance. Its robust construction facilitates smooth parcel movement and resists common industrial stressors.Q: When is the best time to perform maintenance on the conveyor sorting system?

A: Maintenance is straightforward due to the easy-access panels. It is recommended to conduct routine inspections and servicing during scheduled operational downtimes to ensure long-term reliability and avoid unplanned interruptions.Q: Where can this turnkey conveyor sorting system be installed?

A: The systems modular design and ease of assembly make it suitable for a wide range of logistics centers, distribution hubs, and warehouses. Its configurable channel capacity enables adaptation to both large and mid-sized facilities.Q: What is the typical usage of this sorting system in industrial applications?

A: It is primarily used for sorting parcels, packages, and mail in logistics centers. The high throughput rate and accuracy ensure efficient handling of large volumes, streamlining distribution and improving overall operational productivity.Q: What safety mechanisms are integrated into the system?

A: Safety features include emergency stop switches for instant shutdown and overload protection to prevent system damage. These safeguards enhance operational safety for personnel working alongside the equipment.Q: How does this system benefit exporters, manufacturers, and suppliers in India?

A: By automating the sorting process, the system increases speed and accuracy, reduces manual labor costs, and enhances throughput. This enables exporters, manufacturers, and suppliers to handle large consignments efficiently, meeting stringent logistics demands and improving service levels.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

|

ROTHE PACKTECH PRIVATE LIMITED

सर्वाधिकार सुरक्षित.(उपयोग की शर्तें) इन्फोकॉम नेटवर्क प्राइवेट लिमिटेड . द्वारा विकसित एवं प्रबंधित |

जांच भेजें

जांच भेजें